To guarantee your pressure cooker works safely and efficiently, regularly inspect the gasket for cracks, brittleness, or deformation. Replace it if you notice leaks, uneven sealing, or deterioration, as a damaged gasket can cause unsafe pressure buildup. Proper cleaning, storing in a cool dry place, and avoiding over-tightening help prolong its life. Continuing to care for your gasket keeps your cooker performing well—learn more about maintenance and when to replace it to stay safe.

Key Takeaways

- Replace the gasket if you notice cracks, tears, brittleness, or deformation to ensure safety and proper sealing.

- Regularly inspect for leaks or inconsistent pressure during cooking, indicating gasket wear.

- Clean the gasket gently with mild soap and dry thoroughly to prevent deterioration and mold.

- Store in a cool, dry place away from sunlight and heat to maintain gasket integrity.

- Seek professional help if persistent leaks or damage occur despite cleaning and maintenance.

How Your Pressure Cooker Gasket Creates a Seal

Your pressure cooker gasket plays a crucial role in creating a tight seal that allows the cooker to build and maintain high pressure. The gasket’s material compatibility guarantees it works effectively with your specific model and food types, preventing leaks. When the lid is closed, the gasket compresses slightly, filling any gaps between the lid and pot. This compression enhances sealing pressure effectiveness, allowing steam to stay inside and pressure to rise efficiently. Using the right gasket material ensures durability and ideal sealing performance under high temperatures and pressure cycles. Properly chosen gasket materials resist deformation, cracking, or deterioration, which helps maintain a secure seal during cooking. Additionally, material compatibility ensures the gasket remains effective over multiple uses and conditions. Regular inspection and replacement when necessary prevent potential safety hazards, keeping your pressure cooker safe and operating at peak performance. Understanding sealing pressure and gasket material properties helps ensure optimal function and safety during pressure cooking. Ultimately, understanding gasket material compatibility and sealing pressure effectiveness keeps your pressure cooker safe and operating at peak performance.

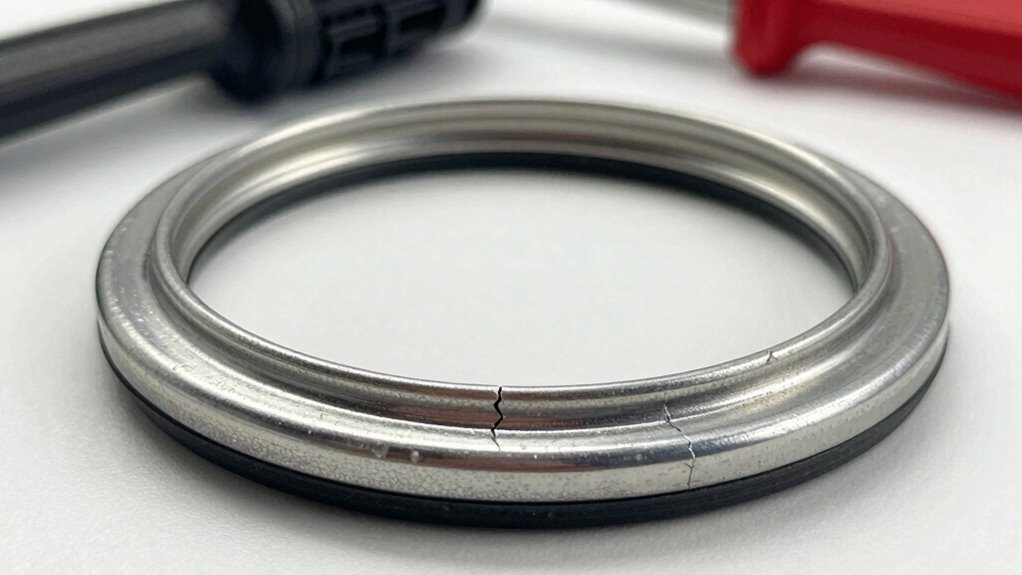

Signs Your Gasket Needs Replacement

Over time, a pressure cooker gasket can show signs that it’s no longer functioning effectively, which could compromise safety and cooking performance. If you notice cracks, tears, or brittleness in the gasket material, it’s a clear sign it needs substitution. Uneven sealing or frequent leaks also indicate deterioration, often caused by material incompatibility with certain foods or cleaning agents. Keep in mind that gasket replacement costs vary, but delaying replacement can lead to more expensive repairs or safety risks. Additionally, a bad gasket may cause longer cooking times or inconsistent results. Regularly inspecting your gasket for these signs helps ensure it maintains a proper seal and keeps your pressure cooker operating safely and efficiently. Understanding the material science of nanotechnology can also shed light on how gasket materials are engineered for durability and safety. Considering proper maintenance practices can extend the lifespan of your gasket and ensure optimal performance. Incorporating advanced materials research into gasket design enhances resistance to wear and environmental factors. Material durability is essential for maintaining a reliable seal over time, especially as innovations in body piercing materials continue to improve gasket resilience and longevity.

Inspect and Maintain Your Gasket to Extend Its Life

You should regularly check your gasket for signs of wear or damage to keep it working properly. Clean it gently with mild soap and avoid harsh chemicals to prevent deterioration. Store your pressure cooker in a dry, cool place to help preserve the gasket’s integrity over time. Additionally, inspecting your gasket for any cracks or deformities can help prevent sudden failures during cooking. Regular testing of your gasket’s seal integrity can also ensure it maintains proper pressure during use. Incorporating proper maintenance routines can further extend the gasket’s lifespan and ensure safety. Proper maintenance also involves replacing the gasket at recommended intervals to ensure safety and optimal performance. Maintaining a seal quality is essential for consistent cooking results and safety.

Regular Gasket Checks

How often should you check your pressure cooker gasket? Ideally, you should inspect it before each use to catch any signs of wear or damage. Regular checks help ensure the gasket material remains flexible, intact, and free of cracks or deformation. Over time, the gasket’s replacement frequency may increase if it shows signs of deterioration, such as hardening or loss of elasticity. By routinely examining your gasket, you can prevent leaks and maintain proper pressure. Keep an eye out for any irregularities around the sealing area. If you notice any issues, replace the gasket promptly. This simple habit extends the gasket’s lifespan and ensures your pressure cooker functions safely and efficiently. Regular gasket checks are a key part of pressure cooker maintenance, helping to prevent accidents and prolong the device’s lifespan. Additionally, being aware of ear wax odor or other unusual smells can help identify potential issues with your appliance or environment that might affect safety, as mental wellbeing plays a role in overall safety practices. Incorporating preventive maintenance and routine inspections into your routine can further help avoid unexpected failures and prolong the gasket’s effectiveness.

Proper Cleaning Techniques

Maintaining your pressure cooker gasket through proper cleaning not only keeps it hygienic but also helps extend its lifespan. To do this effectively, use gentle cleaning brushes to remove food residue and prevent buildup. Regularly inspect the gasket for cracks or deformities during cleaning. Many gaskets are dishwasher safe, making cleanup easier—just place the gasket on the top rack and run a gentle cycle. If your gasket isn’t dishwasher safe, hand wash it with warm, soapy water and a soft brush. Avoid harsh cleaning agents or abrasive scrubbers that could damage the material. Make sure the gasket is completely dry before reinstalling it to prevent mold and odors. Consistent cleaning and inspection keep your gasket in good condition, ensuring safe and reliable pressure cooking. Proper maintenance also involves understanding market standards, which guide the recommended replacement intervals for gaskets to ensure safety and efficiency. Being aware of safety protocols can help prevent potential accidents related to worn or damaged gaskets. Additionally, adhering to manufacturer guidelines can help optimize the gasket’s performance and longevity. Regularly checking for wear and tear is essential to maintain a secure seal and avoid pressure leaks, which can compromise safety. Recognizing the importance of proper storage can also prevent deformation and damage when the pressure cooker is not in use.

Correct Storage Practices

Proper storage practices are key to keeping your pressure cooker gasket in top shape. To prevent deformation or cracking, always clean and dry the gasket thoroughly before storing. Store it in a cool, dry place away from direct sunlight or heat sources, as extreme temperatures can damage the gasket material. Avoid compressing or folding the gasket tightly; instead, lay it flat or keep it in a way that maintains its shape. Using a breathable bag or container helps prevent moisture buildup and mold growth. When inspecting your gasket during storage, check for signs of wear or damage. Regularly inspection and maintenance of your gasket can help identify issues early and prolong its lifespan. Following these storage tips ensures your gasket material stays flexible and effective, extending its lifespan and maintaining a proper seal during pressure cooking.

Step-by-Step Guide to Replacing Your Pressure Cooker Gasket

Replacing your pressure cooker gasket might seem intimidating, but with the right steps, it becomes a straightforward task. First, verify the pressure cooker is completely cool and unplugged for pressure cooker safety. Remove the lid and carefully take out the old gasket, noting how it fits. Check the gasket material to find a compatible replacement—most are silicone or rubber. Clean the gasket groove thoroughly with warm soapy water to remove residue. Then, align the new gasket properly in the groove, pressing it into place to ensure a snug fit. Reassemble the lid, making sure everything is secure. Regularly replacing the gasket when needed keeps your pressure cooker safe and efficient, preventing leaks and maintaining proper pressure during cooking.

Common Mistakes That Damage Your Gasket

Using harsh cleaners can weaken your gasket, so stick to gentle soap and water. Over-tightening the lid puts unnecessary stress on the gasket, leading to cracks or tears. Don’t ignore signs of wear—replacing a damaged gasket early keeps your pressure cooker safe and functional.

Using Harsh Cleaners

Many people make the mistake of cleaning their pressure cooker gasket with harsh cleaners, not realizing how damaging these chemicals can be. Harsh cleaners can cause chemical damage to the gasket material, weakening its flexibility and sealing ability. Using abrasive or strongly scented cleaning agents may seem effective but can deteriorate the gasket faster.

- They can degrade the rubber or silicone material, reducing lifespan

- Harsh chemicals may leave residues that compromise the gasket’s seal

- Over time, this damage leads to leaks and the need for replacement

To preserve your gasket’s integrity, stick to mild soap and warm water. Avoid harsh cleaners entirely, as they do more harm than good, shortening your gasket’s lifespan and risking safety.

Over-tightening Lid

Over-tightening the pressure cooker lid is a common mistake that can cause significant damage to the gasket. When you tighten the handle too firmly, it can distort the lid alignment, putting unnecessary pressure on the gasket. This strain may cause the gasket to warp, crack, or lose its sealing ability over time. Instead of forcing the handle tighter, ensure it’s properly aligned and snug without excessive tightening. Proper lid alignment is vital for a tight seal, but overtightening can compromise the gasket’s integrity. Remember, the goal is a secure seal, not to squeeze the gasket into submission. By avoiding excessive handle tightening, you help extend the gasket’s lifespan and ensure safe, efficient cooking every time.

Ignoring Wear Signs

Ignoring signs of wear on your gasket can lead to leaks and reduced sealing pressure, compromising both safety and cooking results. Over time, gasket material deteriorates, developing cracks, hardening, or losing elasticity. If you neglect these signs, your pressure cooker won’t seal properly, risking steam leaks or insufficient pressure buildup. Common mistakes include using a gasket with visible damage, ignoring persistent leaks, or delaying replacement despite noticeable deformation. These errors diminish sealing pressure and can cause safety hazards. Regularly inspect your gasket for cracks, brittleness, or warping. Remember, a damaged gasket undermines the cooker’s effectiveness and safety, so replacing it at the first sign of wear ensures ideal performance and peace of mind.

Why Regular Gasket Checks Keep Your Pressure Cooker Safe

Regularly checking your pressure cooker’s gasket is essential for safety because a worn or damaged gasket can compromise the appliance’s seal, leading to potential malfunctions or accidents. A secure seal ensures that pressure builds correctly, maintaining pressure safety during cooking. If the gasket’s lifespan has been exceeded or it shows signs of wear, it may leak steam or fail to hold pressure, risking burns or explosions. By inspecting the gasket regularly, you catch issues early, preventing dangerous situations. Maintaining a good gasket condition also prolongs its lifespan, saving you money and effort in the long run. Consistent checks help you stay aware of any deterioration, ensuring your pressure cooker functions safely and efficiently every time you use it.

When to Seek Professional Help for Gasket Issues

Knowing when to seek professional help for gasket issues can save you from potential safety hazards and costly repairs. If your pressure cooker gasket shows persistent leaks, cracks, or warping despite DIY repairs, it’s time to consult a professional. Attempting to fix serious problems yourself might void gasket warranties or compromise safety. Also, if you’re unsure whether your gasket is still covered under warranty, a professional inspection can clarify your options. Seek expert assistance if:

- The gasket has visible damage or deformation that simple cleaning won’t fix

- You’re unsure about the warranty status and need official advice

- Repairs seem beyond your skill level or involve replacing the gasket entirely

Addressing these issues promptly ensures your pressure cooker remains safe and efficient.

Frequently Asked Questions

Can I Use a Different Brand of Gasket in My Pressure Cooker?

Yes, you can use a different brand of gasket in your pressure cooker, but you need to check brand compatibility and gasket materials first. Confirm the replacement gasket fits your cooker model perfectly and is made from safe, heat-resistant materials. Using a gasket designed specifically for your brand guarantees a proper seal, preventing leaks and maintaining safety. Always follow manufacturer recommendations for best performance and longevity.

How Often Should I Replace My Pressure Cooker Gasket?

You should replace your pressure cooker gasket every 1 to 3 years, depending on its gasket lifespan and how often you use your cooker. Regular inspection helps spot signs like cracks, deformation, or loss of flexibility. If you notice any of these, it’s time for a replacement. Following the recommended replacement frequency guarantees a proper seal, safety, and peak cooking performance, preventing leaks and pressure issues.

Are There Any Eco-Friendly Gasket Replacement Options?

Yes, you can find eco-friendly gasket replacement options made from sustainable materials like silicone or natural rubber. These materials are non-toxic and biodegradable, making them better for the environment. When choosing a gasket, look for brands that prioritize sustainability and eco-conscious manufacturing. By opting for these alternatives, you help reduce plastic waste and support environmentally responsible choices in your kitchen.

What Are the Risks of Ignoring Gasket Wear and Tear?

Ignoring gasket wear and tear risks gasket failure, which can lead to safety hazards like steam leaks or sudden pressure release. These issues may cause burns, injuries, or damage to your cooker. Over time, a worn gasket won’t seal properly, compromising pressure control. To stay safe, inspect your gasket regularly and replace it promptly when you notice cracks, hardening, or deformation. Don’t take chances with safety hazards—act early.

Can I Repair a Damaged Gasket Instead of Replacing It?

You can attempt a DIY gasket repair if the damage is minor, like a small tear or deformation. Carefully clean the gasket and use food-safe sealant or adhesive designed for pressure cookers. However, be cautious—if the damage is extensive, it’s safer to replace the gasket entirely. Remember, a properly functioning gasket ensures safety and ideal pressure cooking, so don’t compromise if repairs seem unreliable.

Conclusion

By keeping a close eye on your gasket, you’re fundamentally giving your pressure cooker a heartbeat, ensuring it runs smoothly and safely. Regular inspections and timely replacements are like tuning a finely crafted instrument—preventing breakdowns before they strike. Remember, a well-maintained gasket is your first line of defense against kitchen mishaps. When in doubt, don’t hesitate to seek professional help—your peace of mind is worth more than a moment’s oversight.